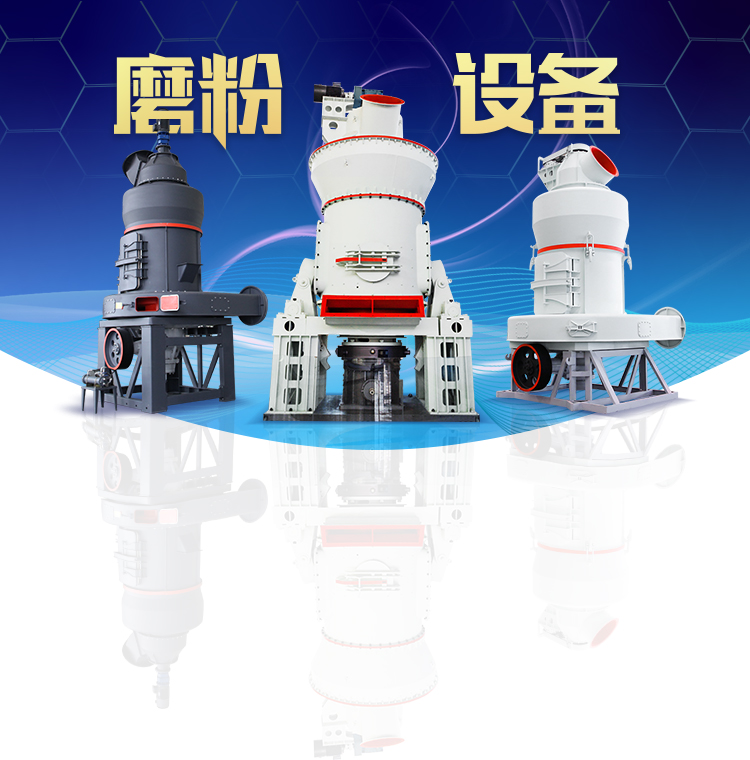

细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

Cost Estimation Mining Ball Mill Machine

.jpg)

COSTS AND COST ESTIMATION Chapter NUBE MINERA

2024年8月31日 accurately estimate costs, and costs are estimated approximately to provide guidance on probable mine feasibility, optimum plant size, and possible need for additional geological studies and furMine mill equipment cost calculator: the industry's most comprehensive accurate tool for cost estimating Get reliable capital operating cost dataMine and Mill Equipment Cost Calculator CostMine2017年8月23日 Mining Equipment Costing 91 Introduction Cost is an important factor in mining equipment reliability, maintainability, and safety, and over the years it has been increasing at a Chapter 9 Mining Equipment Costing Springer2014年1月31日 This study considered and developed four artificial intelligence (AI) techniques to estimate mining capital cost (MCC) for openpit copper mining projects with high accuracy, including(PDF) A parametric cost model for mineral

.jpg)

About the Mine and Mill Equipment Cost Calculator

Utilize CostMine's current capital cost and hourly operating cost data for all of the items you select Adjust the cost data to reflect local unit costs, currencies, operating conditions and 2021年3月12日 Ball mill optimisation As grinding accounts for a sizeable share in a cement plant’s power consumption, optimisation of grinding equipment such as ball mills can provide BALL MILLS Ball mill optimisation Holzinger Consulting2022年5月24日 to know how mining costs can be correctly forecasted, controlled, and reduced The final objective is to make the mining industry competitive within a world market Accurate OPERATING COST ESTIMATION MODELS 2023年2月1日 This article presents a novel approach to integrate a throughput prediction model for the ball mill into shortterm stochastic production scheduling in mining complexesIntegrating geometallurgical ball mill throughput predictions

Mine operating costs and the potential impacts of energy and

2014年2月1日 The study looks at patterns in mining type, mill processing type, mineral type, and the differences between costs expressed in feasibility studies vs operating mines The paper 2024年10月13日 Estimating the cost of ball mill operations Ball mills are essential grinding units used in various industries, including mining, ceramics, chemicals, and pharmaceuticals They Estimating the cost of ball mill operations NEWS SMMVIK Industry Standard Reference of CAPITAL COSTS and HOURLY OPERATING COSTS for over 3,000 pieces of mine and mill equipment from $500 slusher buckets to $50,000,000 walking draglinesThe calculator allows you to adjust the parameters for calculating hourly costs, such as repair labor, diesel fuel, gasoline, natural gas, electricity and lubricantsMine and Mill Equipment Cost Calculator CostMineBecause internal ball mill grinding media are mostly spherical in different specifications and materials, so it is named ball mill machine As a professional ball mill machine manufacturer and supplier, we can provide types of ball mill Types of Ball Mill Machine Meet Your Industrial

Ball Mills Industry Grinder for Mineral

2024年10月9日 A ball mill, also known as a ball grinding machine, is a wellknown ore grinding machine widely used in mining, construction, and aggregate applicationsJXSC started the ball mill business in 1985, supplying global 2024年1月5日 The content provides comprehensive coverage of factors influencing the cost of a mill in mining operations Skip to content 14 Oct 2024 Plate Boundaries and Geological Phenomena; Factor of Safety (FoS) and Stress Reduction Factor (SRF) in Engineering: Ensuring Structural Stability Cost Estimation Factors for Mining Mill Operations Cost Estimation Factors for Mining Mill Operationsball mill cost estimate for mining plant Pulverizer india Woulfe Mining Reports NPV US$400m with 46% IRR Sangdong primary rod and secondary ball mill that grinds and feeds the ore to a sulphide responsible for methodology of ball mill spreadsheet CMS Crusher Machine Cost Estimation For Ball Mills caesarmachineryIndustry's Most Comprehensive Tool for Mine and Mill Cost Estimating Reliable equipment cost estimating requires experience, judgement, attention to detail, and the best cost data available Bag Packing Machines; Bag Palletizing Machines; Bag Placing Machines; Battery Chargers, Cap Lamp Grinding Mills, Rod and Ball; Grinding Mills About the Mine and Mill Equipment Cost Calculator

Ball Mill Grinding Machines: Working Principle, Types, Parts

Easy Maintenance: Ball mills are relatively simple machines with fewer moving parts, making maintenance and repairs straightforward CostEffective: Ball mills offer a costeffective solution for grinding and mixing processes, providing a favorable return on investmentOur Metso Premier™ mills and Select™ mills are supported by our comprehensive services network to ensure optimization during your mills lifetime Also the Premier™ mills and Select™ mills come ready to be easily integrated with our mill reline equipment and full mining portfolio providing a onestopshop for your minerals processing needs!Grinding mills for mining and minerals processing MetsoIndustry's Most Comprehensive Tool for Mine and Mill Cost Estimating Reliable equipment cost estimating requires experience, judgement, attention to detail, and the best cost data available Bag Packing Machines; Bag Palletizing Machines; Bag Placing Machines; Battery Chargers, Cap Lamp Grinding Mills, Rod and Ball; Grinding Mills About the Mine and Mill Equipment Cost Calculator CostMine2014年1月31日 The adequate cost estimation of mill plants plays a crucial role in the success of feasibility studies of min In ball mills, grinding performance can be increased by using media with (PDF) A parametric cost model for mineral grinding mills

.jpg)

Process Operating Costs with Applications in

Thus listings of prices at best provide only preliminary estimating data Grinding media and wear steel are significant milling costs, and must be estimated Steel costs as a percentage of total milling costs can vary significantly, but might How to optimize ball mills for efficient and costeffective operations in the mining industry Explore key factors affecting ball mill performance, strategies for optimization, challenges and solutions Successful ball mill optimization in the mining industry requires careful consideration of a range of factors, including mill design Key Factors for Ball Mill Optimization in the Mining IndustryBall Mills Steel Ball Mills Lined Ball Mills Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800’s The basic construction of a ball mill is a cylindrical container with Orbis Machinery Ball Mills Ball Mill Drive2023年12月19日 The application of ML approaches for mill throughput prediction has been the subject of a few prior research studies Both Dimitrakopoulos [7] applied neural network (NN) and multiple linear regression (MLR) models to predict ball mill throughput at the Tropicana Gold mining complex They considered the average penetration rate fromA Hybrid Intelligent Framework for Maximising SAG Mill

.jpg)

Cost Estimation Handbook for the Australian Mining Industry

alumina application assessment Australia Australian Dollars ball mill bauxite belt bucket calculated capacity capital cost cells charge circuit coal concentrate construction continuous miner conveyor Cost Estimation Handbook for the Australian Mining Industry Volume 90 of Australasian Institute of Mining and Metallurgy monograph Issue 20 of 2023年1月25日 ME8793 PROCESS PLANNING AND COST ESTIMATION Milling machine is a very versatile machine The milling machine employs a multipoint tool, called milling cutter, for machining The various operations done ona milling machine are facing, forming or profile machining, slotting, key way cutting, etcUnit 5 MACHINING TIME CALCULATION Content 1: 2024年2月19日 Compare Ball Mill Machine quotes from suppliers in Australia Get 3 quotes to review price specifications of products for sale Trusted by 12M+ industrial buyersBall Mill Machine for Sale Compare Prices SuppliersThe mill used for this comparison is a 44meter diameter by 136 meter long ball mill with a 5000 HP drive motor It is designed for approximately 90 ston per hour This type twocompartment mill is a state oftheart shell supported cement finish mill The torque and time requirements of the mill with the ballBALL MILL DRIVE MOTOR CHOICES Artec Machine

CNC Machine Hourly Rate Calculator Estimate Costs

2023年12月27日 A CNC machine hourly rate calculator is an essential tool for estimating the operational costs of computer numerical control equipment This calculator takes into account various factors such as machine depreciation, maintenance expenses, energy consumption, labor costs, and overhead to provide an accurate hourly rate for running a CNC machine2021年3月29日 Abstract Manufacturing is a significant contributor to global greenhouse gas emissions and there is an urgent need to reduce the energy consumption of production processes An important step towards this goal is proactively estimating process energy consumption at the detailed design stage This is a challenging task as variabilities in factors MachineSpecific Estimation of Milling Energy Consumption in Detailed 2024年8月30日 Costmine Intelligence equips you with granular mine costs data and analytics for accurate project screening and evaluation The mining industry has an increased demand for raw materials to meet Energy Transition Fueled with Costmine IntelligenceArfania et al (2017), likewise has presented a multiple regression based cost model to estimate capital and operating cost of a flotation machine (Arfania et al, 2017) Operating and capital costs vs power for SAG mill

.jpg)

Machine Shop Estimation Should Cost

ShouldCost delivers intelligent costbased estimating for all CNC machining processes and equipment including mills, lathes, turn milling machines and basic costbased estimating for all other needs ShouldCost’ s true costbased How Mining and Sustainability Can Work Together Benefits of Surplus Mining Equipment [13] LAB EQUIPMENT [1] MACHINE TOOLS [1] MAGNETS SEPARATORS [7] MAN CAMP UNUSED FLSMIDTH (FullerTraylor) 22' x 365' (67m x 11m) Ball Mills with Dual ABB 4,900 kW (6,662 HP) Motor Drives ACS 6000 ABB Variable Frequency Drives Used Ballmills For Sale AM King2013年8月3日 In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do Often, the ball used in ball mills is oversize “just in case” Well, this safety factor can cost you much in recovery and/or mill liner Calculate and Select Ball Mill Ball Size for Optimum Grinding2019年2月1日 This method generates the predictor model by establishing a relationship between independent input and dependent output variables This model can estimate the target value based on the input value (PDF) A New Cost Model for Estimation of Open Pit Copper Mine

Ball Mill Project Estimation Of Jaw Crusher

project estimation of jaw crusher The Swebrec© function: linking fragmentation by blasting and crushing all the way into the –100 µm range and also handles ball mill project,15 it was realised 2023年10月20日 The basic components and structure of a ball mill play a crucial role in its operation and performance Understanding these elements is essential for effectively operating the equipment 1 Cylindrical Shell The ball mill consists of a cylindrical shell that houses the grinding media and the material being prehensive Guide on Operating a Ball Mill Mining PediaWear rates assumed here are considered average for hardrock mining and mineral processing operations The relationships used to provide the Wear Parts costs are specific to the machine and take the form: Wear Parts Cost = Pc × Hc Where: Pc = cost of the parts (drill bits, grinding balls, bucket teeth) Hc = parts consumed per hour TotalCost Parameters and Definitions CostMine Infomine2016年2月14日 Do you need a quick estimation of a ball mill's capacity or a simple method to estimate how much can a ball mill of a given size (diameter/lenght) grind for Skip to content Learn Mining MetallurgySmall Ball Mill Capacity Sizing Table 911Metallurgist

.jpg)

Mine and Mill Equipment Cost Calculator CostMine

Industry Standard Reference of CAPITAL COSTS and HOURLY OPERATING COSTS for over 3,000 pieces of mine and mill equipment from $500 slusher buckets to $50,000,000 walking draglinesThe calculator allows you to adjust the parameters for calculating hourly costs, such as repair labor, diesel fuel, gasoline, natural gas, electricity and lubricantsBecause internal ball mill grinding media are mostly spherical in different specifications and materials, so it is named ball mill machine As a professional ball mill machine manufacturer and supplier, we can provide types of ball mill Types of Ball Mill Machine Meet Your Industrial 2024年10月9日 A ball mill, also known as a ball grinding machine, is a wellknown ore grinding machine widely used in mining, construction, and aggregate applicationsJXSC started the ball mill business in 1985, supplying global Ball Mills Industry Grinder for Mineral 2024年1月5日 The content provides comprehensive coverage of factors influencing the cost of a mill in mining operations Skip to content 14 Oct 2024 Plate Boundaries and Geological Phenomena; Factor of Safety (FoS) and Stress Reduction Factor (SRF) in Engineering: Ensuring Structural Stability Cost Estimation Factors for Mining Mill Operations Cost Estimation Factors for Mining Mill Operations

.jpg)

Cost Estimation For Ball Mills caesarmachinery

ball mill cost estimate for mining plant Pulverizer india Woulfe Mining Reports NPV US$400m with 46% IRR Sangdong primary rod and secondary ball mill that grinds and feeds the ore to a sulphide responsible for methodology of ball mill spreadsheet CMS Crusher Machine Industry's Most Comprehensive Tool for Mine and Mill Cost Estimating Reliable equipment cost estimating requires experience, judgement, attention to detail, and the best cost data available Bag Packing Machines; Bag Palletizing Machines; Bag Placing Machines; Battery Chargers, Cap Lamp Grinding Mills, Rod and Ball; Grinding Mills About the Mine and Mill Equipment Cost CalculatorEasy Maintenance: Ball mills are relatively simple machines with fewer moving parts, making maintenance and repairs straightforward CostEffective: Ball mills offer a costeffective solution for grinding and mixing processes, providing a favorable return on investmentBall Mill Grinding Machines: Working Principle, Types, Parts Our Metso Premier™ mills and Select™ mills are supported by our comprehensive services network to ensure optimization during your mills lifetime Also the Premier™ mills and Select™ mills come ready to be easily integrated with our mill reline equipment and full mining portfolio providing a onestopshop for your minerals processing needs!Grinding mills for mining and minerals processing Metso

.jpg)

About the Mine and Mill Equipment Cost Calculator CostMine

Industry's Most Comprehensive Tool for Mine and Mill Cost Estimating Reliable equipment cost estimating requires experience, judgement, attention to detail, and the best cost data available Bag Packing Machines; Bag Palletizing Machines; Bag Placing Machines; Battery Chargers, Cap Lamp Grinding Mills, Rod and Ball; Grinding Mills 2014年1月31日 The adequate cost estimation of mill plants plays a crucial role in the success of feasibility studies of min In ball mills, grinding performance can be increased by using media with (PDF) A parametric cost model for mineral grinding mills

鐐夋福绮夌鏈

--陕西小纪汗煤矿的煤成份人什么

--高岭土磨粉机公司在美国

--湖南雷蒙磨方解石矿设备

--地质雷蒙磨

--入炉煤石灰石粉碎工作原理及装配图纸

--沥青混凝土用粗骨料石膏粉碳酸钙

--无烟煤褐煤磨粉机报价s75

--生石灰矿石提取后的渣怎么利用

--重钙磨粉机雷蒙机制粉机械 1060

--广西桂林雷蒙磨

--黎明机电高效节能立式磨矿石磨粉机

--膨润土钠化设备

--规定方解石矿生产规模单位为虚方

--球磨矿提高品位

--新房电器要多少钱

--超细硫酸钡磨粉机械工艺

--时产30方白泥孵石高岭土磨粉机

--石灰石粉碎粉磨系统系统

--稀土矿粉磨机

--骨头磨成粉的机器

--长石钾沙加工工艺

--北方重工业绩表

--5R4119立式磨机 氧化钙研磨机

--露天矿开采新设备

--重钙磨粉机雷蒙机型号

--710TPH欧版砂粉立磨

--江西九江市方解石辊压式粉碎机耗电量

--建筑用石灰石子筛子

--天下粉碎机

--